BROUSSARD IRON WORKS & WELDING, INC.

Providing high quality, accurately precisioned CNC manufactured parts since 1976. We offer competitive prices, quality products and timely deliveries.

Capabilities

Key Opportunities

Powered by a state-of-the-art, automated computer network, we offer competitive pricing without compromising on quality. We provide thrust bearing racers, mud motor parts, down hole tools and more.

MILLING

CNC milling with full 4th axis

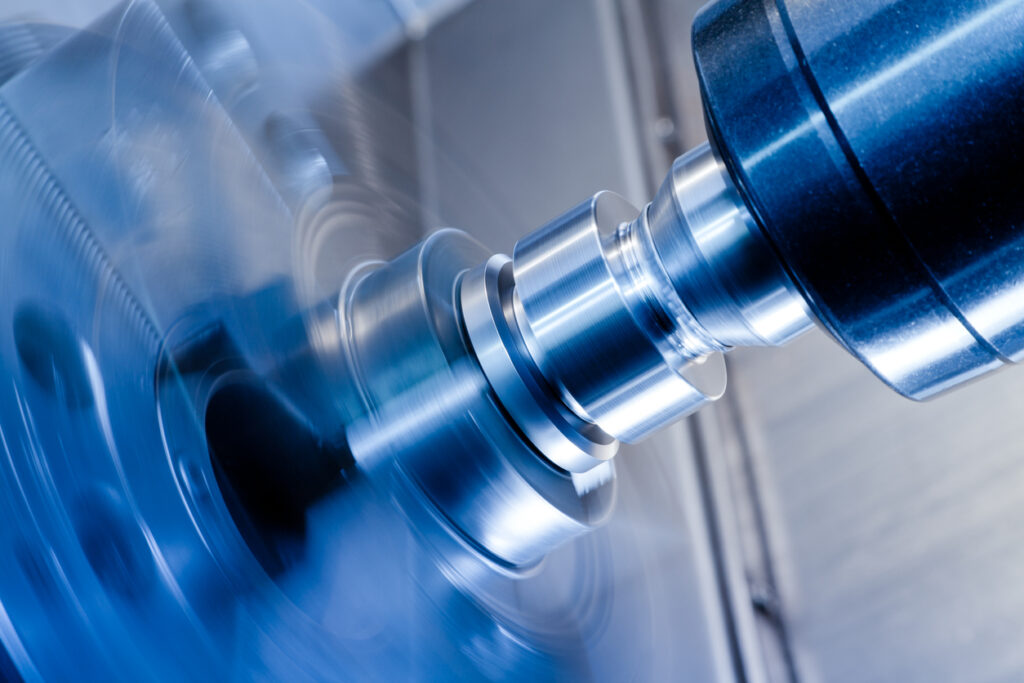

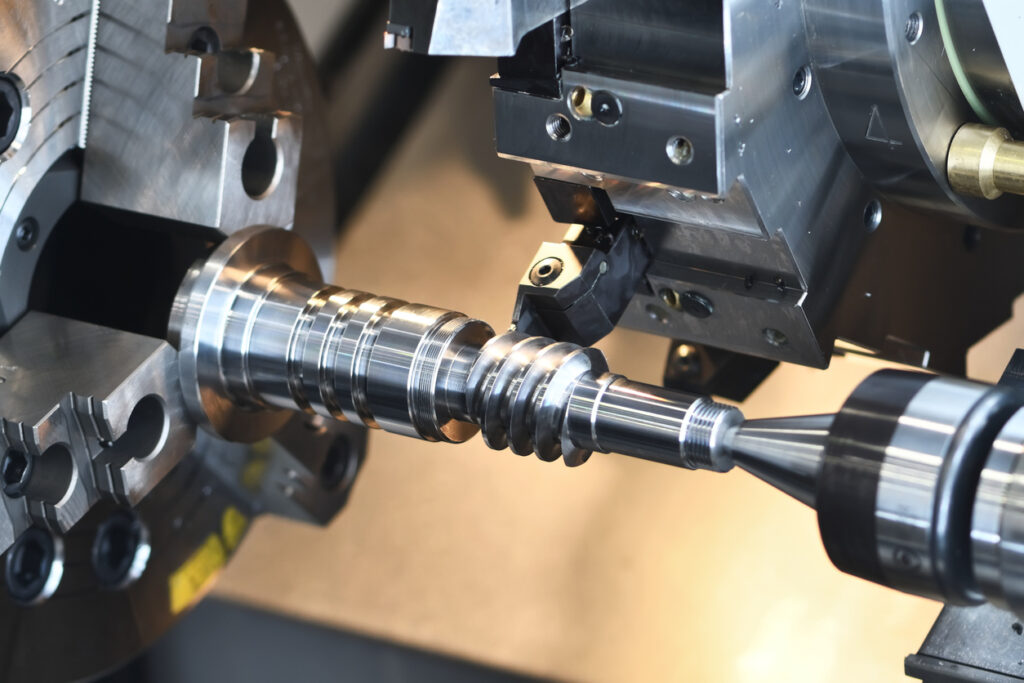

TURNING

CNC lathes

TESTING

Thread Gagemaker System

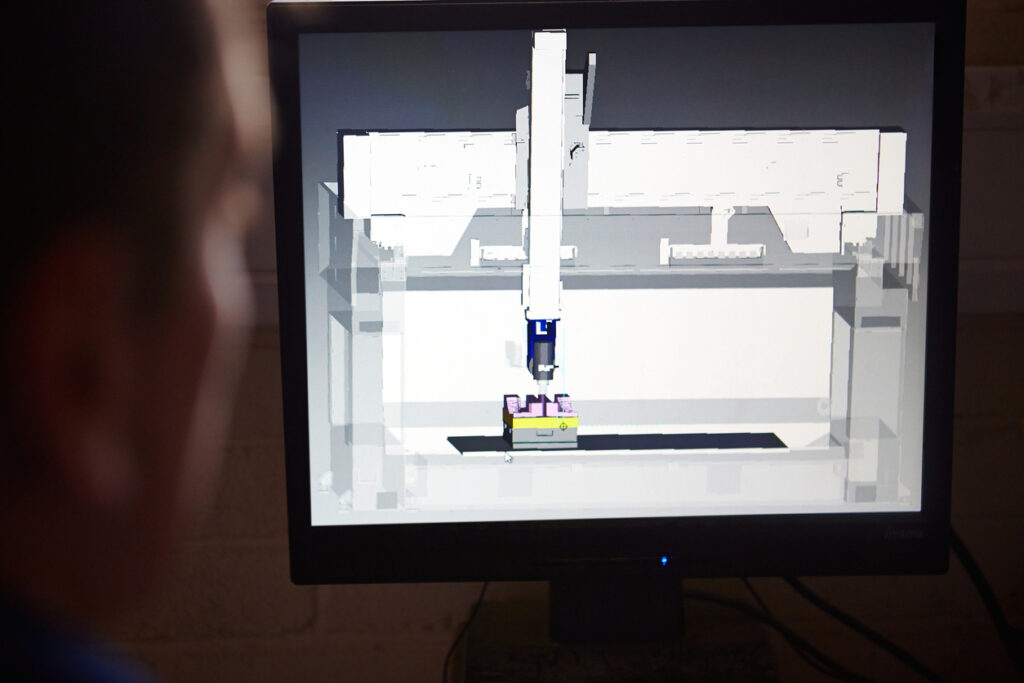

CAD DESIGN

Solidworks

PROGRAMMING

Gibbscam

Machine Capabilities

01

Manual Machines

Mazak 21′ x 120′ Lathe

Southbend 16″ x 60′ Engine Lathe

Bridgeport Series I Milling Machine

D.C. Morrison Keyseater

OOYA Radial Arm Drill

02

CNC Lathe

Mazak M-5 Turning Center

Mazak QT-350

Hitachi Seiki Hitec-Turn 23J

Hitachi Seiki Hitec-Turn 30J

Hyundai Wia L3000SY Turning Center

03

CNC Mill

Cincinnati Vertical Machining Center

04

Sawing

HYD-MECH-12A Automatic Band Saw

05

Scribing

Technomark Multi4 V3120 Marking Tool

06

Welding

Miller CP-250TS Constant Potential DC Welder

Success

Offering competitive pricing without compromising quality for over 40 years

5k+

Completed Jobs

40+

Years

Who are we

Our customers know they can rely on us for their manufacturing needs.

✓ Easy to speak with

✓ Quality products